Sales: 84270 07400 Email us: sales@3dwds.in

|

Sales: 84270 07400 Email us: sales@3dwds.in

|  Support: 84270 07401 Email us: support@3dwds.in

Support: 84270 07401 Email us: support@3dwds.in

Sales: 84270 07400 Email us: sales@3dwds.in

|

Sales: 84270 07400 Email us: sales@3dwds.in

|  Support: 84270 07401 Email us: support@3dwds.in

Support: 84270 07401 Email us: support@3dwds.in

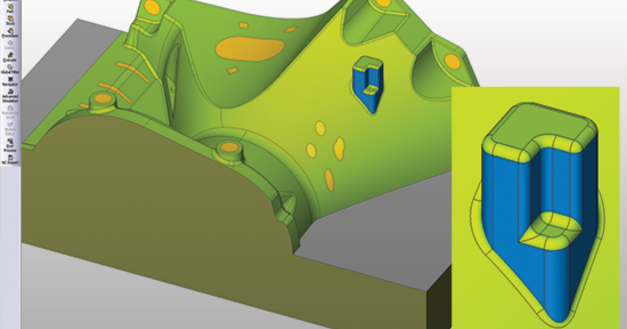

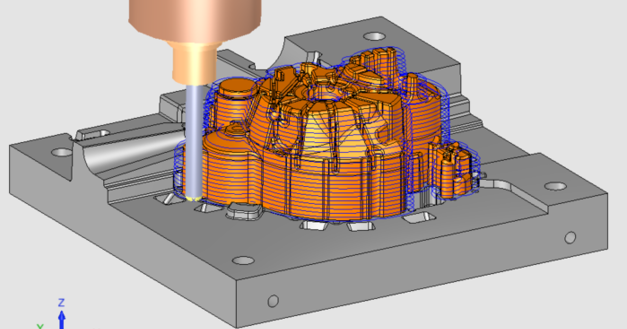

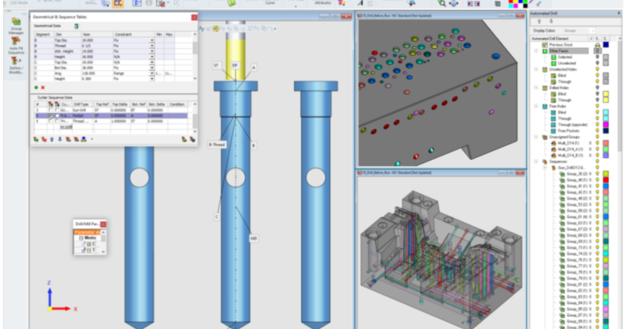

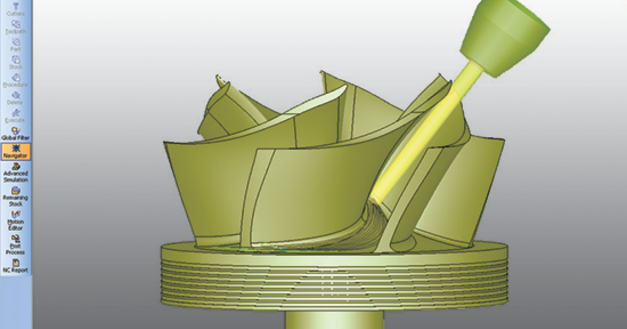

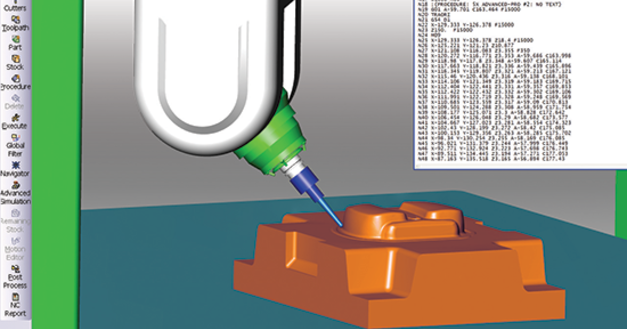

Cimatron NC Programming enables fast, efficient NC programming for molds, dies, plates, and discrete manufacturing with one of the most competitive selections of 2.5- to 5-axis milling and drilling strategies on the market and strong built-in CAD tools, analysis tools, and simulators.

All the CAD you need for the best machining results:

Our solutions enable you and your team to quickly transform new ideas into great products.

Ready To Buy Request for Demo Whatsapp Free Trial Call Us Email Us

Sales: 8427007400 / Email: sales@3dwds.in

Support: 8427007401 / Email: support@3dwds.in

Punjab, Ambala, Delhi, Jammu & Kashmir, Himachal Pradesh

SCF 26, Phase 2, Urban Estate,

Focal Point, Ludhiana - 141010, (Punjab) India