Sales: 84270 07400 Email us: sales@3dwds.in

|

Sales: 84270 07400 Email us: sales@3dwds.in

|  Support: 84270 07401 Email us: support@3dwds.in

Support: 84270 07401 Email us: support@3dwds.in

Sales: 84270 07400 Email us: sales@3dwds.in

|

Sales: 84270 07400 Email us: sales@3dwds.in

|  Support: 84270 07401 Email us: support@3dwds.in

Support: 84270 07401 Email us: support@3dwds.in

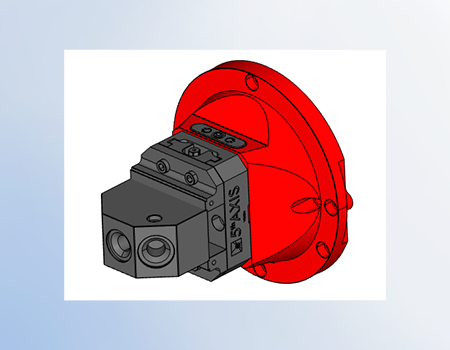

BobCAM for SOLIDWORKS is our new Gold Certified CAM add-in. It's fully integrated, single- window, industry-proven CAM technology for SOLIDWORKS. Utilize our easy-to-use, powerful toolpath wizard technology and streamline your workflow in both part or assembly files. The latest BobCAM for SOLIDWORKS has powerful toolpath features, it’s easy to use and it’s affordable for shops of all sizes.

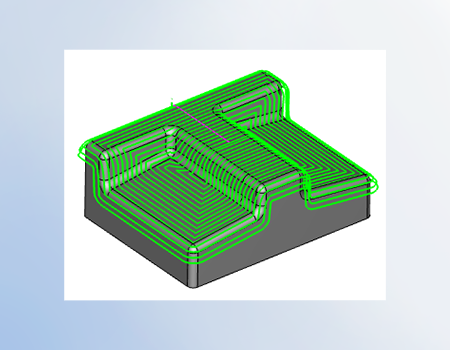

SOLIDWORKS CAM software for Milling delivers the functionality you need to program everything from simple 2.5 axis cutting to complex 3, 4 & 5 axis simultaneous milling. It incorporates a wide range of advanced & fully associative machining strategies using a simple wizard-driven interface that makes programming faster, smarter and easier. The software offers multiple time-saving features including Dynamic Machining Strategies™ to reduce programming time and increase efficiency. BobCAM also includes advanced simulation and reporting tools that allow you to test and confirm your work.

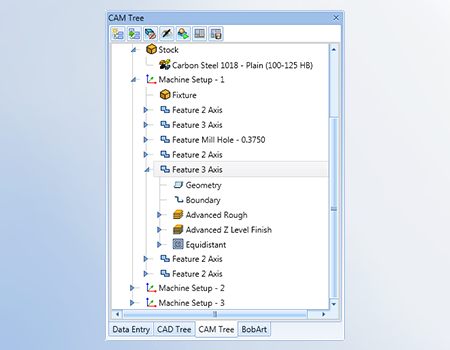

The best of both worlds come together in BobCAD’s CAM Tree, Operations and Features. BobCAD’s machining features gives users the ability to create single operations per feature or to customize multiple operations tied to a single feature. This flexible programming workflow eliminates redundant tasks required in operation only CAM Trees.

The best of both worlds come together in BobCAD’s CAM Tree, Operations and Features. BobCAD’s machining features gives users the ability to create single operations per feature or to customize multiple operations tied to a single feature. This flexible programming workflow eliminates redundant tasks required in operation only CAM Trees.

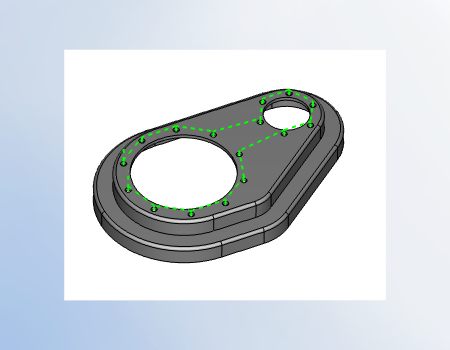

2, 3, 4 and 5 axis hole making is simple with BobCAD’s intuitive hole making wizards. Choose from Standard Drilling, Cross Drilling, or Multiaxis Drilling. Select points, arcs or solid models to define hole locations, sizes and depths. Users can quickly Spot, Drill, Tap and Counterbor with a single machining feature. Post your holes in separate moves or canned cycles.

Offering a wide variety of powerful operations for 2D / 2 ½ D cycles. Work from wireframe sketches, surface edges or faces. More powerful and efficient than conversational programming. Capture and reuse machining processes on future projects to reduce overall programming time, while working directly on user created or customer supplied CAD files.

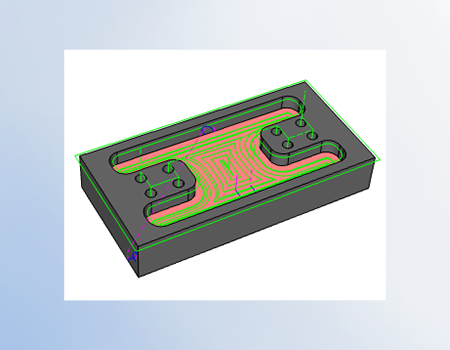

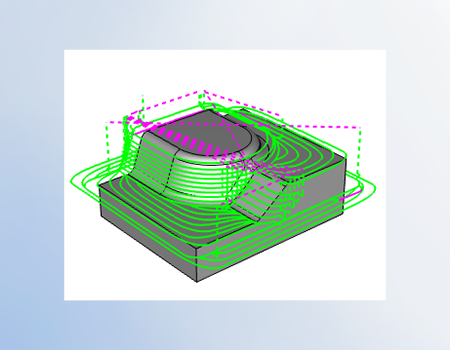

Simple or Complex BobCAD’s got you covered with up to 21 machining strategies that tackle the most difficult of projects. Advanced features to control where toolpath is created, what it avoids and it’s feedrates. Superior surface finishes is what you expect and BobCAD delivers!

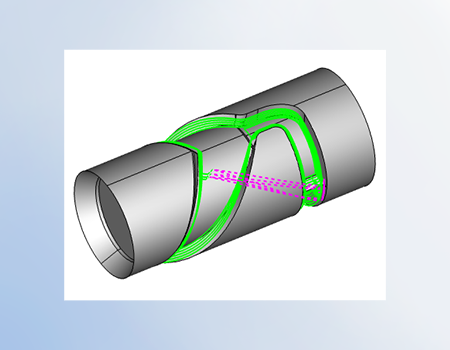

Indexing, Wrapping Groups, Rotary, Advanced Rotary and True 4 axis are all fully supported. Get the most out of your machine when using your 4th axis with BobCAD.

True, full-featured simultaneous toolpath strategies for advanced multiaxis part programming. Controlling tool tilt, avoid areas, feed rate mapping and much more that unlocks the full potential of your 5 Axis CNCs. Table Table, Head Table, Head Head 5 axis machine configuration with advanced posting feature to support Machine Comp in Z, Machine Hybrid compensation RTCP,TCP,TCPC, DWO, Origin Tracking and coordinate rotation.

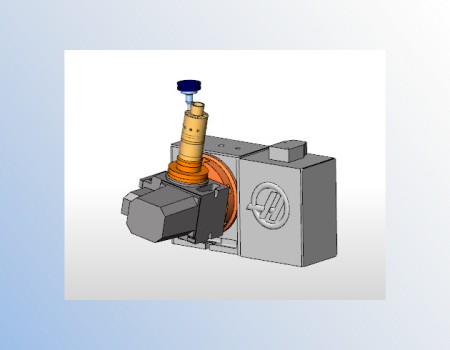

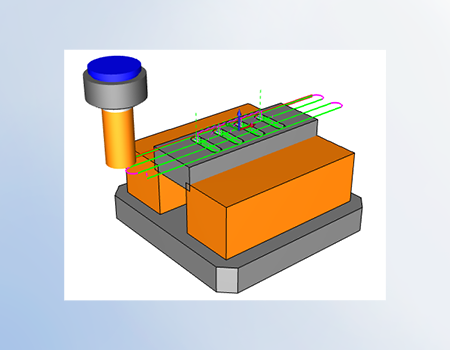

Get a real view of what’s happening on the machine before you ever cut a chip. BobCAD’s solid simulation is loaded tools to validate your machining process, gouge check, find left over stock and much more.

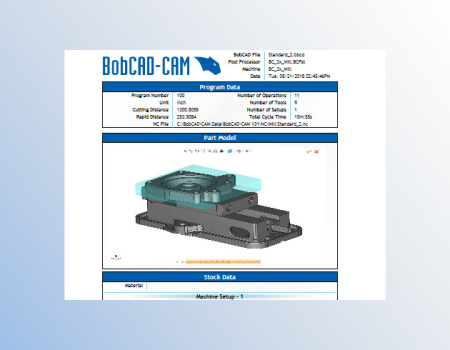

Documenting your programming process with live feedback as you fine tune your toolpath features are available in many forms. CAM Tree Flyouts, Setup Sheets, Tool Assignment , Gouge and Collision reports, Move Operation and Sequence statics: All created automatically and easily accessible at any stage of machining.

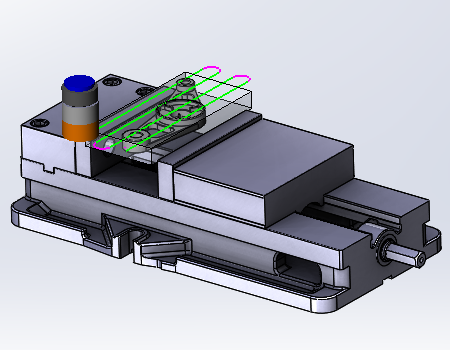

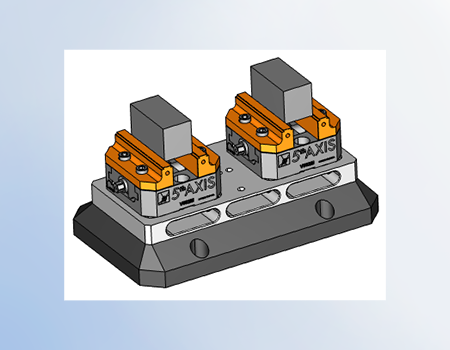

Virtual simulation of your setup and workpiece is standard in BobCAD CAM V32, select display and avoid fixtures gaining better control and confidence in your part programming.

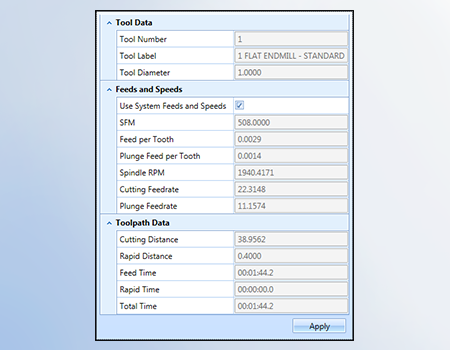

Top level editing and display of critical parameters of the Job, Tools, Stock, Machine Setup, Features, Operations and more. Faster edits and quicker display of those settings user want to see or change most.

High efficiency, high speed and highly used by manufacturers all over the world! Adaptive toolpaths are quickly becoming the standard for 2, 3, 4 and 5 axis roughing. Reduce your cycle times, extend tool life and minimize wear and tear on your equipment with this modern toolpath strategy.

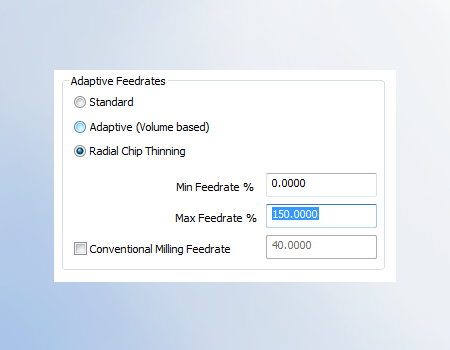

Multiple feedrate adjustments and mapping to optimize tool motion. Eliminate dog leg moves, slow down material entry exit and link moves, volume based, radial chip thinning, surface radius and tool contact feed optimization, feed control zone and more!

Process planning, quoting or scheduling? Use BobCAD’s Toolpath statistics and get detailed automatic reports about: Time Data, Toolpath Extents, Toolath Data and Speed and Feeds.

Display your tool and holder as you step through or play your toolpath operation. Rapid graphical feedback for direction of cut, tool hangout, sequence ,cutter location, tool orientation and more.

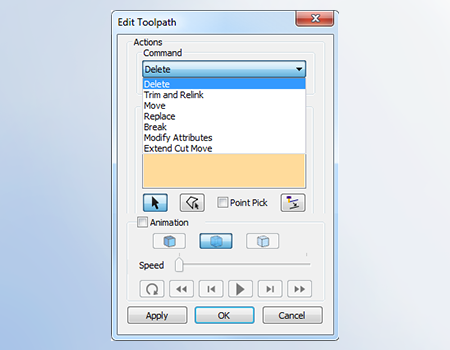

Fully customize your toolpaths for unique or challenging scenarios. By deleting, trim and relink, move, replace, break, modify attributes or extend cut moves. Users can directly modify their toolpaths outside of the toolpath wizards parameters.

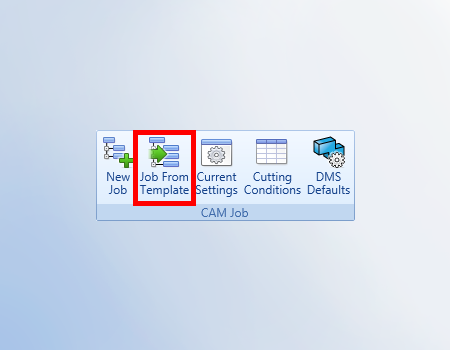

Maximize your shops programming efficiency by saving a Job Tree as a template. Allowing users to shortcut programming by pre populating the Job Tree with stock, setup locations, machining features and more. Faster programming for in-house processes or dedicated machining centers and applications.

Create multiple copies of machining features or setups using either a toolpath or workoffset pattern. Post copies in long code or with multiple work offset locations ( G54, G55, G56). Great for production with 2 or more same part workoffset locations.

2.5 Axis

3 Axis

4 Axis

5 Axis

Surface Based Toolpath (3, 4, & 5 Axis Output)

In order to use BobCAM for SOLIDWORKS™, you must have SOLIDWORKS™ 2014 or later installed on the same computer that you choose to install BobCAM for SOLIDWORKS™. The following are system requirements for using Windows Vista, Windows 7,Windows 8 or Windows 10 x64.

Recommended System Requirements:

Minimum System Requirements:

When using physical media (disk) to install the BobCAM software, the optical drive being used must support DVD-ROM disks. The system requirements listed above are suggested for running the BobCAM for SOLIDWORKS™ add-in. Please adhere to the system requirements listed inside SOLIDWORKS™ for optimum performance within the SOLIDWORKS™ system.

Our solutions enable you and your team to quickly transform new ideas into great products.

Ready To Buy Request for Demo Whatsapp Free Trial Call Us Email Us

Sales: 8427007400 / Email: sales@3dwds.in

Support: 8427007401 / Email: support@3dwds.in

Punjab, Ambala, Delhi, Jammu & Kashmir, Himachal Pradesh

SCF 26, Phase 2, Urban Estate,

Focal Point, Ludhiana - 141010, (Punjab) India